Epoxy can be a form of resin that's established by mixing two components with each other - a resin plus a hardener. When these two parts are merged, a chemical reaction occurs, resulting in a robust, durable materials that could be used for several different programs. Epoxy is noted for its superb adhesion, chemical resistance, and mechanical Houses, making it a preferred option for an array of industries, which include design, automotive, aerospace, and marine.

Epoxy is available in a number of types, together with liquid, paste, and solid, and can be used as an adhesive, coating, or filler. It can be placed on an array of surfaces, like metallic, wood, concrete, and plastic, rendering it a flexible material for numerous projects. Epoxy is additionally obtainable in a variety of colors and finishes, making it straightforward to customize to suit the particular needs of a undertaking.

Epoxy is frequently utilised together with other materials, for example fiberglass or carbon fiber, to generate composite elements which can be lightweight and robust. It can be applied being a protective coating for surfaces that happen to be exposed to harsh environments, like chemical spills or Excessive temperatures. General, epoxy is a versatile and durable materials that has an array of applications throughout a number of industries.

How Epoxy is Made use of

Epoxy is Utilized in an array of purposes, from industrial to creative. In the construction field, epoxy is usually employed being an adhesive for bonding components collectively, which include metallic to steel or metallic to concrete. It is usually employed as being a coating for flooring and walls to deliver safety against chemical substances, abrasion, and humidity. Within the automotive field, epoxy is utilized for bonding body panels and restoring broken pieces. Additionally it is applied being a protecting coating for undercarriages together with other metal parts to circumvent corrosion.

Within the maritime field, epoxy is utilized for fixing fiberglass boats and developing personalized parts. It is also made use of like a protecting coating for hulls and decks to forestall h2o intrusion and injury from maritime organisms. Within the aerospace sector, epoxy is utilized for bonding composite elements collectively to create light-weight and robust structures. Additionally it is utilised like a protective coating for plane components to offer resistance towards Intense temperatures and severe environments.

During the art entire world, epoxy is utilized for creating sculptures, jewellery, along with other ornamental products. It can be blended with pigments and other products to build one of a kind types and finishes. Over-all, epoxy is a flexible product that could be used in a variety of programs, from industrial to inventive.

Benefits of Utilizing Epoxy

There are many Added benefits to making use of epoxy in several purposes. Among the main benefits of epoxy is its great adhesion Homes. When properly applied, epoxy types a strong bond With all the substrate, creating a strong and extensive-Long lasting connection. This causes it to be a super option for applications in which sturdy adhesion is required, for instance in construction and automotive industries.

Another advantage of making use of epoxy is its chemical resistance. Epoxy is highly proof against a wide range of substances, which includes acids, solvents, and oils. This makes it a great option for apps in which publicity to severe chemical substances is common, including in industrial configurations or marine environments.

Epoxy also provides excellent mechanical Attributes, which include substantial toughness and toughness. This causes it to be a great option for purposes where toughness and affect resistance are crucial, like in the aerospace sector or for producing customized components in the marine sector.

Along with its Bodily Attributes, epoxy also offers aesthetic Gains. It is available in a wide range of colours and finishes, which makes it straightforward to customise to fit the precise requires of the task. This can make it a perfect option for applications where visual appeal is vital, like in the art environment or for ornamental coatings in household or professional settings.

Total, epoxy features a wide array of Rewards that make it an ideal option for many alternative purposes across several industries.

Different Types of Epoxy

There are several different types of epoxy readily available that you can buy, Just about every with its individual exceptional Homes and applications. Just one widespread style of epoxy is named "epoxy resin," which happens to be a transparent liquid which can be blended with many additives to develop custom formulations. Epoxy resin is commonly utilized for casting and encapsulating apps, like generating decorative merchandise or encapsulating electronic parts.

Guidelines for Dealing with Epoxy

Working with epoxy demands mindful consideration to detail and correct procedure to make certain successful final results. A person important suggestion for working with epoxy is always to thoroughly Adhere to the producer's Recommendations for mixing the resin and hardener. Correct mixing is important for acquiring the specified Qualities from the epoxy and guaranteeing a strong bond.

Safety Precautions when Employing Epoxy

Although epoxy delivers quite a few Added benefits for various applications, it's important to get appropriate protection safeguards when working with this material. A single crucial protection precaution when utilizing epoxy is to work inside of a well-ventilated location to stay away from inhaling fumes through the resin and hardener. Epoxy fumes is usually irritating to the respiratory procedure and should lead to dizziness or nausea if inhaled in higher concentrations.

Environmental Impact of Epoxy

Though epoxy delivers many Positive aspects for various apps, it is vital to contemplate its environmental effect. One probable environmental issue with epoxy is its manufacturing system, which may contain the usage of chemicals that could be dangerous into the setting Otherwise properly managed. It's important for manufacturers to acquire suitable actions to attenuate the environmental effect of manufacturing epoxy by way of liable sourcing of Uncooked products and squander administration tactics.

Kirk Cameron Then & Now!

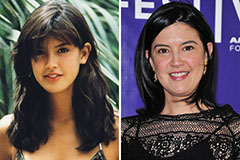

Kirk Cameron Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!